Chat Online

Productcategorieën

Zhejiang Mineral Slag Drying Equipment Began to Load and Transport

The mineral slag drying project that the Zhejiang customer cooperated with me is currently progressing smoothly. After the equipment is completed, our company will arrange the delivery immediately. The main body and accessories of the equipment will be officially shipped after the completion of the loading. The following is the mineral slag drying shot by the staff Pictures of the delivery site of the dryer.

The mineral slag drying equipment of this project is designed and manufactured by our company for the production needs of local customers. The equipment has a large processing capacity and applies the drying process independently developed by the Zhengzhou Dingli technical team. It will bring convenience for customers to process a large amount of slag and other materials. The workshop staff cooperated closely, and the equipment loading work was very smooth. During the loading process, our quality inspectors carefully checked the equipment list to ensure that the equipment and accessories were formally shipped after they were intact.

The technical team responsible for the installation of the project will also go to the installation site in the near future to carry out the preliminary preparations to ensure that the follow-up work is carried out smoothly. The progress of the project will continue to be followed by logging on to the Zhengzhou Dingli website.

Another Slime Drying Equipment is Completed and Officially Shipped

The Zhengzhou Dingli workshop continues to be busy. Recently, another coal slime drying equipment in Zhengzhou Dingli has been completed. After the equipment is completed, it has been officially shipped after the inspection by the quality inspection department. The following is the equipment delivery site.

This project is a coal slime drying project cooperated by our company and a coal company customer in Shanxi. Our company provides customers with slime dryer equipment within the specified construction period. The equipment has been officially shipped and is responsible for the installation of the project. The team will also rush to the installation site in the near future so that the follow-up work can be carried out smoothly after the equipment arrives there. The follow-up progress of the project will continue to be paid attention to.

Shanxi is a key area in Zhengzhou for the construction of coal slime drying projects. Our company has also built many drying projects in the local area. We have established long-term cooperative relations with many customers on coal slime drying projects. Welcome everyone to come to the factory to discuss project cooperation. Survey the local case site.

Shandong Seaweed Residue Dryer Equipment Officially Put Into Production

The seaweed residue drying equipment purchased by the Shandong customer from our company has been tested after installation and commissioning. The customer is satisfied with the effect of the equipment test. The seaweed residue dryer for this project has been officially put into production. The following are the staff The shot of Shandong seaweed residue dryer equipment on-site pictures.

Zhengzhou Dingli is a large-scale dryer equipment manufacturer with 20 years of experience in drying project construction. Shandong customers formally appreciate our mature product series and rich project experience, and choose to cooperate with our company to create seaweed residue drying. In the process of project construction, the meticulous work attitude of Dingli people has also won the recognition and praise of customers. After the equipment is put into production, our company will continue to provide follow-up technical support and other after-sales services.

Zhengzhou Dingli's technical team designs the drying project plan, designs and manufactures equipment one-to-one according to the needs of customers, and also provides turnkey projects such as equipment installation and commissioning. Currently, coal dryers and feed dryers are launched according to the characteristics of materials , Dregs dryer, biomass fuel dryer, mineral soil, slag drying equipment, etc., welcome to call 18037308442 for equipment consultation.

Bangladeshi Cassava Residue Drying Equipment Delivered On Schedule

The cassava residue drying equipment ordered by Bangladeshi customers has been delivered smoothly as scheduled.

Cassava residue is a by-product of cassava starch extraction. The main indicators include crude fiber, crude ash, and moisture. The dried cassava residue has high nutritional value and is the main additive material for feed processing. Has a relatively extensive application market. The large-scale cassava residue drying equipment manufactured by our company can turn cassava residue into treasure.

75-85% moisture content material first with special dehydration machine removing a part of moisture, the moisture removed around 68%, then send into the dryer by screw conveyor to realize downstream drying. Under the effect of the inner shoveling plate, materials are taken and scattered constantly, and move in the spiral forward method. Inside mixing blade device will be fully stirred and crushed material, material and hot air through full heat exchange, the rapid evaporation of water vap orization, reaching about 35%, discharged by the screw conveyor, then send into the semi-wet material crusher, crushed material size below 1mm, then into pulse air drying process, within 10-15s the material quickly removed to 10% by the cyclone discharger and Pulse bag dust collector recovery dry powder, exhaust emissions amount to the national standard requirement, to complete the entire drying process. The drum cleaning device is installed inside the drum to prevent the material from adhering to the cylinder wall.

China Dingli is a professional manufacturer of dehydration and drying equipment, welcome customers in need to leave messages for consultation.

Guizhou Straw Dryer Installation Site

Guizhou customer ordered a set of straw drying equipment from our company, and it has arrived at the customer's equipment installation site. Our after-sales installation team will start the formal installation and commissioning work.

Straw dryer is a kind of biomass dryer, which is our main equipment. This equipment is of a huge production, high efficiency, and energy-saving, small floor space. Compared with common dryer machines, it saves energy by 30%-50%, thus saving energy and drying cost to the maximum.

Working principle of straw dryer: The crushed materials of which the moisture is about 35%-55% are sent into the roller by conveyor to realize downstream drying. Under the effect of inner shoveling plate, materials are took and scattered constantly, and move in spiral forward method. Through three layers (inner, middle and outer layer), heat exchange are realized between material and hot air medium. The materials that achieve drying effect move forward fastly and are discharged out of the roller. Wet materials that still don't achieve drying effect couldn' t move fastly due to self-weight, and are dried completely during the controlling route, thus achieving drying effect. Material moisture is decreased to 12%-15%. After the whole drying process is completed, materials are discharged by screw conveyor. Inside the roller is installed with vibrating cleaning device, which prevents materials from bonding to the cylinder wall.

Zhengzhou Dingli is mainly engaged in dehydration and drying equipment, which supports customization and free design schemes. Customers who want to know can consult our engineers online.

Thailand Eucalyptus Bark Drying Equipment Loaded And Shipped

Last year, a Thai customer ordered a complete set of eucalyptus bark drying equipment from our company. The production has now been completed, and the truck has been successfully loaded and shipped to the port.

Biomass dryer is our main equipment. It can be used to dry biomass waste, wood chips, garden waste, straw, bark, wood chips and other biomass wastes. This dryer has high efficiency, energy saving, and small floor space. Compared with other dryer machines, it saves energy by 30%-50%, thus maximum saving energy and drying cost.

High humidity materials forming experts Zhengzhou Dingli company according to the market demand, company targeted development of material pellet fuel production line equipment. It has an exclusive patent and can customize various high humidity material drying production line equipment. For more details, please leave a message for consultation.

Liaoning Straw Dryer Production Line Officially Put Into Operation

Recently, another straw dryer production line of our company has been put into production. The following is a live case sharing:

Straw dryer drying speed is fast, the drying intensity is high, and the residence time is short. Fully automatic control, stable and reliable operation. The coal-burning system adopts a fuzzy controller, and the temperature can be automatically adjusted to ensure the quality of the dried products. Safe production and reliable operation. The multi-stage waste heat is used in the system, and the comprehensive thermal efficiency is increased by more than 10%, which greatly reduces the drying cost.

The straw dryer is a large-scale continuous drying equipment. The whole set of equipment consists of a coal-fired hot blast stove, an inlet and outlet equipment, a rotary drum dryer, high and low temperature pipelines, a dust removal system, a lifting conveying system, a finished product cooling system, and a finished product. Storage, electronic control system, steel frame and other equipment and institutions.

Zhengzhou Dingli is a professional manufacturer of large-scale industrial tumble dryers. Mainly engaged in biomass dryer, feed dryer, organic fertilizer dryer, coal slime dryer etc.

Henan Sprayed Corn Husk Drying Project Officially Put Into Operation

The sprayed corn husk dryer is a by-product of the production of starch and germ after the corn is humidified. The main component is corn husk. Then spray the corn yellow syrup with high protein and energy content to greatly increase the energy, protein and amino acids contained in it. After drying, it becomes corn spray protein. Recently, the sprayed corn husk drying project built by our company for Henan customers has been officially completed. The project has been put into production. The following is a picture of the project site.

The sprayed corn husk dryer is mainly composed of a heating source, a feeder, a feeder, a rotary drum, a discharger, an induced draft fan, an unloader, a power distribution cabinet and a cooling system. The project is designed and manufactured by our company for the needs of Henan customers. After the equipment is manufactured, the delivery will be arranged immediately. After the equipment arrives at the installation site, our installation team will immediately start the project installation work. At present, the equipment installation work has been successfully completed. After the test machine Officially put into production, the customer is very satisfied with the effect of material drying during the test machine, and at the same time, the working attitude of our technical team during the project installation process has also won customer praise. At present, the equipment of the project has been officially put into production, and our company will continue Provide follow-up technical support and services.

The sprayed corn husk dryer production line equipment is one of our main product series. This equipment can quickly dry a large amount of corn husk materials into feed to meet the needs of farmers in different regions. At present, Zhengzhou Dingli has launched according to market demand Various configurations of spray corn husk drying production line equipment, welcome to leave a message for consultation.

Beer lees is a by-product of brewing production, which has the characteristics of low price, large output, rich nutrients, and good fattening effect. The development of distiller's grains into unconventional feed can greatly alleviate the shortage of feed resources, reduce breeding costs, and improve economic benefits. Dingli distiller's dried grain dryer production line complete sets of equipment have been put into use in many beer companies and feed processing companies around the world, and have created considerable economic benefits.

Brewer's spent grains dryer mainly consists of heat source, feeding machines, feeder, rotary drum, discharging machine, draft fan, discharge and power distribution cabinet.

BSG with 85% moisture is delivered into the screw dehydration machine (or belt dehydration machine) and dehydrated to 50% to 60% moisture content. Then the dehydrated product was delivered into the rotary dryer by screw conveyor for the drying process. High-temperature air heated by furnace could have full mass and heat exchange with BSG, taking away the moisture.

Zhengzhou Dingli Group is a major manufacturer of dehydration and drying equipment. Interested customers can leave a message for consultation.

A few days ago, the good news was returned from the scene of Youyu, Shanxi Province. The production line of large capacity coal slime dryer produced by Dingli company has been successfully commissioning and put into production.

According to market demand, Dingli Coal Slime Drying Production Line adopts a new heat source that uses clean fuel with sufficient heating and cleanliness. At the same time, uses a multi-stage dust removal device with high-efficiency dust removal. This project embodies the two advantages of Dingli equipment environmental protection and energy-saving. Shanxi is an important market for our coal slime drying projects. At present, many project feedback devices are in normal operation and have good benefits.

Dingli coal slime drying machine belongs to customized production, according to customer needs, thus meeting the different needs of each customer. Therefore, it is more targeted, scientific, and reasonable, and more rigorous in technical processing.

Dingli Coal Slime Dryer is suitable for slime, peat, coal, and so on. Our company can optimize drying technology and equipment selection and configuration services according to slime characteristics, production scale, quality requirements, application requirements, cost control, automation level, site conditions. Welcome to consult online.

Recently, news came from the Shandong sawdust drying project: the installation and commissioning of the project was completed, and the project was officially put into production. The following is a picture of the Shandong sawdust drying production line.

In the Shandong sawdust drying production line, our company provides customers with high-quality drying production line equipment and installation and debugging services. During the equipment installation process, the Zhengzhou Dingli installation team closely cooperates with local customers to promote the project installation work and equipment installation in an orderly manner. Afterwards, our technical team arranged follow-up testing and technical training. The production line was smoothly tested and praised by customers. The equipment was officially put into production. Our company will continue to provide technical support and other services.

Sawdust drying production line equipment has always been one of Zhengzhou Dingli’s main product series. Equipment can be designed and manufactured according to the needs of customers in different regions for processing sawdust and other resources. Customers in need are welcome to come to the factory to buy.

On December 2, the manufacturing of Jiangsu Spent Grain Drying Equipment was completed. After inspection by the quality inspection department, it has been officially shipped to the project site.

Brewer grains, the main by-product of the beer industry, is a residue from the extraction of soluble carbohydrates after fermentation of barley. Beer grains are rich in protein, amino acids, and trace elements, and have high nutritional value. Dingli Brewer grains rotary dryer is suitable for drying high humidity materials such as brewer grains, white lees, spent grain, etc.

With the diversification of technology, Dingli Brewer Grains Dryer mainly includes a steam tube drum dryer and a three-layer drum dryer. According to the global development trend of biomass fuel, it also supplies beer spent grain dryers equipped with biomass burners.

Dingli Brewer's Grain Drying Production Line has a high degree of mechanization, large production capacity, and can be continuously operated, convenient operation, low maintenance cost, low power consumption, good uniformity of product drying. For more detailed information, you can consult online. Looking forward to your inquiry.

After the production of the straw dryer ordered by our customer was completed, the technical team responsible for the project immediately arranged the delivery. After the busy morning of the workshop workers, the equipment was loaded and officially shipped. The following is a picture of the equipment delivery site.

In the straw drying project that our company cooperates with customers, our company provides customers with straw drying production line equipment that meets their production needs and subsequent equipment installation and commissioning services according to the contract. Before the equipment is shipped, our company has checked the equipment list many times, and officially shipped the equipment after confirming that the equipment is in good condition. The technical team responsible for the installation of the project will set off to the installation site in the near future to prepare the preliminary work so that the installation can be carried out smoothly after the arrival of the equipment. You can log on to the Zhengzhou Dingli website to keep an eye on the subsequent installation of the project.

Our straw dryer is suitable for wheat straw, corn straw, soybean straw, cotton straw, etc. The equipment has a large processing capacity and can be designed and manufactured according to the production needs of different customers. Customers in need are welcome to come to the factory to buy.

Traditional Chinese medicine slag is the waste of pharmaceutical factories and enterprises, which is a kind of biomass waste. The traditional treatment methods of medicine residue are: discarding, landfilling, etc., but this will cause environmental pollution and waste of resources. With the enhancement of environmental protection, pharmaceutical factories currently choose to dry the waste medicine residue into pellet fuel or Organic fertilizer for resource reuse.

The traditional Chinese medicine residue dryer is mainly composed of heat source, dispersing device, belt feeder, feeder, rotary drum, belt discharger, induced draft fan, unloader and power distribution cabinet.

The working principle of the Chinese medicine residue dryer is as follows: During the drying process, the medicine residue enters the dryer and is divided into the following work areas: One is the guide area. The medicine residue enters this area and quickly evaporates water in contact with the high temperature hot air. When the guide angle's copy board is moved, it will lead to the next working area if no adhesion is formed; the second is the cleaning area, where the slag is copied by the copy board to form a material curtain state, and the material will easily form a bonding roller when it falls Wall phenomenon. In this area, because the equipment is designed with a cleaning device, the cleaning device can clean the materials adhering to the inner wall very reasonably. In this process, the cleaning device also breaks the agglomeration of the material, thereby increasing the heat exchange The area increases the drying rate; the third is the inclined lifting plate area, where the medicine slag has been in a low-moisture loose state, and the material has no adhesion phenomenon in this area. After the heat exchange, the material reaches the required moisture state. Enter the final discharging area; the fourth is the discharging area, the drum is not equipped with a copy plate in this area, and the material rolls to the discharge port in this area to complete the entire drying process.

Zhengzhou Dingli Group is a professional manufacturer of large-scale drying equipment. The company has undertaken more than one hundred large-scale drying equipment construction projects at home and abroad. The equipment is exported to dozens of countries at home and abroad. Mainly engaged in the construction of biomass drying and granulation production line, manure organic fertilizer granulation production line, beer lees drying as feed production line construction, coal slime drying production line construction and other businesses. Interested customers are welcome to leave a message for consultation.

Zhengzhou Dingli's coal slime drying project in the Inner Mongolia market has been officially completed. The following is the equipment site.

The Inner Mongolia market has always been a key area for our company to build slime drying projects. Our company has built many slime drying projects in Inner Mongolia and has established long-term cooperative relationships with many customers. This project is another slime drying project built by our company in the local area. During the project construction work, the Zhengzhou Dingli technical team demonstrated their skillful technology and dedicated work attitude, which was well received by local customers. The equipment has been officially put into production. The company will continue to provide customers with quality services and technical support.

Zhengzhou Dingli is a large-scale coal slime drying equipment manufacturer, which can provide high-quality equipment and services according to customer needs. Customers in need are welcome to come to the factory to purchase.

Zhengzhou Dingli’s coal slime drying project for another customer in Guizhou is currently being installed smoothly. The main body of the equipment has been installed. The following is a picture sharing of the equipment site.

The slime dryer equipment that our company built for customers in Guizhou this time is designed and manufactured in strict accordance with the customer’s production requirements. The equipment selection is optimized from the processing capacity, moisture demand, heat source and dust removal configuration. I believe that the equipment will help corporate customers to dry coal slime quickly. At present, the main equipment installation work of the project has been completed, and the follow-up work is progressing in an orderly manner under the cooperation of the Dingli installation team and local customers. The project is expected to be completed within the specified construction period. You can log on the Zhengzhou Dingli website to keep an eye on the progress of the project.

Zhengzhou Dingli is a large-scale coal slime drying equipment manufacturer. The equipment is designed and manufactured according to customer needs. It can be equipped with a variety of heat sources, multi-stage dust removal and desulfurization devices according to the needs of local environmental impact assessments. Welcome to contact us online.

Zhengzhou Dingli is a large-scale dehydration and drying equipment manufacturer with more than ten years of experience in the construction of dehydration and drying projects. The equipments are exported to more than 30 countries in six continents including Asia, Africa, Europe, North America, South America, Oceania, and has established long-term cooperative relations with hundreds of customers. Zhengzhou Dingli has won praises and purchases from many customers due to its technical advantages and perfect technical services, the sales performance has also continued to rise. Recently, Zhengzhou Dingli has climbed to the peak again. In September, Zhengzhou Dingli’s monthly shipment volume exceeded 40 vehicles, achieving another milestone in the history of shipments. The following are some pictures of the shipment site in September.

Zhengzhou Dingli’s orders and multiple workshops continue to be busy. All departments pay close attention to details during the equipment production process. After the equipment is completed, the delivery will be arranged in time. The quality inspection department will inspect the equipment before it leaves the factory. To the place of installation, Zhengzhou Dingli delivered more than 40 vehicles in a single month in September alone, setting a new benchmark in the history of Dingli’s delivery and setting a milestone.

Zhengzhou Dingli has its own technical research and development team, which has been focusing on the research and development and technological innovation of dehydration and drying equipment and other products, engaged in the research, production, sales, technical development, technical service, technical consultation, etc. of dehydration drying equipment, and has established a good reputation in the drying industry. Zhengzhou Dingli is committed to the development and production of a series of technical products such as biomass pellet fuel production line, feed dehydration and drying equipment, organic fertilizer production line, coconut shredded coconut chaff dehydration and drying equipment, and coal (mud) upgrading equipment. In the future, Zhengzhou Dingli looks forward to working with more customers to build high-quality drying projects, and go hand in hand for common development.

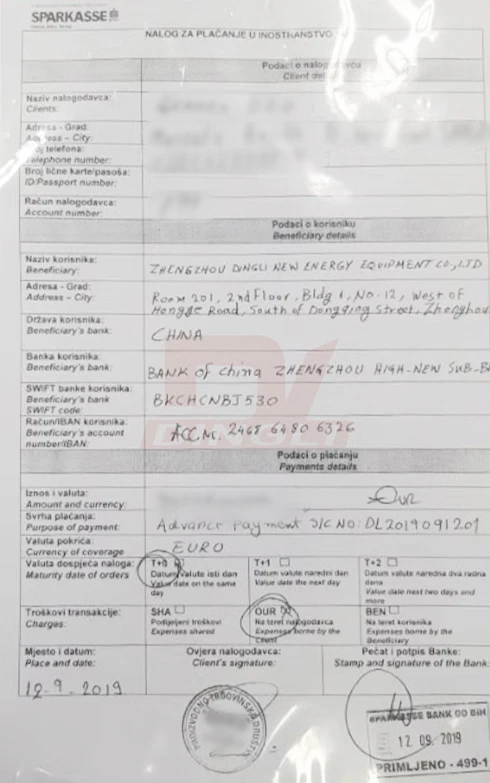

During the National Day holiday in October, Indian customers signed a belt dehydrator equipment order contract with our company, and the customer has already paid a deposit for friendly cooperation.

Zhengzhou Dingli belt dewatering equipment is suitable for various materials such as medicine residue, bean dregs, distiller's grains, starch residue, sludge, etc. Our company will design and manufacture equipment according to the material characteristics of Indian customers. The process flow of Dingli belt dewatering equipment: the material passes through the conveyor, is transported to the hopper of the dewatering machine, and is evenly spread on the filter belt through the spiral distributor. The filter belt will be flattened by the material layer with the operation of the equipment, so that the thickness of the material is completely uniform. Then the upper and lower two fully tensioned ring-shaped filter belts clamp the material layer, driven by the driving roller, the pair of rollers in the dewatering zone are mechanically squeezed for many times to press out a large amount of water.

Zhengzhou Dingli belt-type dewatering equipment has been used in many projects. Our company has nearly 20 years of equipment manufacturing experience. Indian customers are fancying our high-quality equipment and rich experience and choose to cooperate with our company. The pre-design and production work of the company has almost started, and I believe that our company will provide customers with high-quality equipment and services within the specified construction period.

At the end of September, Dingli Group completed the production of the Pomace Rotary Dryer equipment for Italian customers. After the precision inspection by the quality inspection department, the equipment was officially shipped out. The following is a picture of the Italian pomace dryer equipment shipped.

Dingli Group is large-scale high-humidity material dehydration and drying equipment manufacturer, which can provide domestic and foreign customers with high-quality equipment and project construction services. This time the pomace drying project cooperated with our company and Italian customers, the equipment has been completed. Follow-up services will be launched after the equipment arrives and installed. The pomace dryer for this project is designed and manufactured by Dingli in strict accordance with the contract and in accordance with the customer’s processing capacity requirements, moisture requirements, and heat source dust removal accessories. The company’s self-developed drying process and detailed equipment will bring convenience to the local processing of pomace and other materials.

Dingli provides Pomace Dryer Equipment, the high-humidity material drying equipment is also suitable for distiller's grains, potato residue, starch residue, bean dregs, sugar beet residue, and other materials. There are many equipment specifications and models. You can contact us for more detailed information.

On September 7, good news came from the Liuzhou alcohol grain dryer project site. After several days of hard work by our after-sales installation team, the alcohol grain dryer was installed and ready to enter the trial stage. The following is the live picture:

Alcohol lees dryer is a mature drying product of our company. It is suitable for the drying of corn distiller’s lees, buckwheat distiller’s lees, white distiller’s lees and beer lees. It adopts high-temperature hot air drying process, and has a three-layer rotary drum drying structure with a processing capacity. The characteristics of large and small footprint save time and labor and labor, so the cost of drying one ton of alcohol grains is also greatly reduced. At the same time, the use of three-stage progressive dust removal and purification equipment, the drying process is clean and environmentally friendly.

The follow-up work of Guangxi's large-scale corn alcohol grains will follow up. If you want to know more about the project, please contact us.

After the insect drying production line equipment ordered by our Malaysian customers is completed, our company will immediately arrange the equipment delivery. The following is the equipment delivery site.

This morning, the workers in our workshop carried out the equipment loading work. During the equipment loading process, our staff paid attention to details and carefully checked the equipment list to ensure that the main equipment and accessories were complete. After the equipment loading work was completed, the equipment list was checked again Make sure that there is no omission of formal delivery.

The insect drying production line equipment of this project is designed and manufactured by our company according to the needs of customers. This equipment can quickly dry the materials into high-protein feed, etc. At present, the equipment has been officially sent to Malaysia, and the insect drying equipment will be installed later. You can log on to the Zhengzhou Dingli website to learn about the progress of debugging.

In summer, many installation teams of Zhengzhou Dingli continue to work on the front line of the project. Recently, with the cooperation of the Dingli installation technical team and local customers, the Sichuan project has officially completed the finishing work. The equipment of the project will be tested in the near future, and soon after the test is completed Put into production, the following is the site map of Sichuan food waste treatment equipment.

The environmental protection of kitchen waste has always been a topic of concern to everyone. Zhengzhou Dingli has launched a variety of kitchen waste treatment production line equipment according to market demand. After the customer in Sichuan put forward the demand, our company immediately designed and formulated the production line plan. The equipment of this project It is made by our company in response to customer needs. During the equipment installation process, our installation team closely cooperates with local customers, pays attention to project details and other issues, grasps quality and keeps pace with progress, and creates a high-quality kitchen waste treatment equipment project for customers. Currently this project The finishing touches have been completed and the customers are quite satisfied.

Zhengzhou Dingli is a manufacturer of kitchen waste treatment equipment. It has more than ten years of project construction experience. Currently, it has built kitchen waste drying treatment projects in many areas. Dingli large-scale kitchen waste treatment equipment can quickly dispose of kitchen waste. The equipment has high efficiency, welcome customers in need to come to the factory to buy.

The belt dewatering machine purchased by our customer in Changshu successfully arrived at the destination and the installation was completed. In this project, we arranged professional commissioning personnel to follow the car to the equipment installation site to carry out installation and commissioning work, and will provide a series of guidance, training, after-sales and other services in the later stage.

The belt dehydrator is mainly composed of a main engine, an air compressor, an air source processor, an electric control box, and a net washing water filter. The host part is mainly composed of frame, feeding hopper, filter screen, tensioning device, deviation adjustment device, driving mechanism, scraper discharge device, various bearing seats and rollers, sewage tank, net washing device, etc. The belt dehydrator is widely used for the dehydration of distiller's grains, potato residue, bean dregs, sludge and other materials.

Zhengzhou Dingli specializes in the development and production of dehydration drying equipment. Besides belt dehydrators, our products also include spiral dehydrators and various tumble dryers. If you need it, please consult us.

Today, good news came from the after-sales department of Dingli. The soybean dregs flash dryer purchased by Jiangsu customers from our company has been installed and put into use. The following is a live picture.

The flash dryer is the main equipment for drying okara to make cat litter. Making cat litter from legume waste can be used to mask the smell of cat urine and feces. In this case, the Jiangsu customer used a flash dryer to dry the bean dregs to make cat litter. Flash dryers are also widely used in the dispersion and drying of granular, powder, paste and filter cake-like pseudo-agglomerates in the chemical, pharmaceutical, building materials, food, feed and other industries. The flash dryer has the advantages of small footprint, low energy consumption, high thermal efficiency, and continuous batch production.

The okara flash dryer is a mature design in Zhengzhou Dingli. The dried bean dregs are of good quality and large output. It is a very mature, stable and efficient drying equipment. For more information, you can consult online.

After the completion of corn alcohol grains drying production line ordered by Guangxi customers, the equipment delivery immediate start. The following is the equipment hoisting and delivery site.

This set of corn alcohol lees drying equipment is designed and manufactured by our company for the production needs of customers. The equipment is designed and manufactured in terms of processing capacity, moisture and other requirements. During the equipment manufacturing process, our company’s new drying process is applied. The application of this process will greatly improve equipment drying efficiency. After the equipment is made, our company arrange the delivery immediately, and use two cranes to complete the hoisting work of the equipment. During the equipment loading process, our quality inspectors carefully check the equipment list and pay attention to the details of the equipment loading process of the corn alcohol lees drying production line. After the loading is completed, check again to ensure that the production line equipment and accessories are in good condition. The equipment is currently on its way. The shipment to Guangxi is expected to arrive at the installation site soon. The installation technical team responsible for the project will also go to the site as soon as possible to start the related work of the project installation.

Corn alcohol lees drying equipment belongs to our company's high-humidity material dryer equipment series. The equipment can be designed and manufactured according to customer needs, which can meet the drying needs of tens to hundreds of tons per day, and provide follow-up services such as equipment installation and commissioning. Customers in need can consult online.

The slime dryer equipment purchased by our customers from Shaanxi Shenmu was formally sent to the installation site after production. At present, the Shenmu slime drying project in Shaanxi is progressing smoothly, and the equipment has entered the installation process. The following is the equipment installation site.

This project is designed and manufactured for customers according to their production needs. After the equipment arrives at the installation site, the installation team responsible for the project immediately starts related work, coordinates with local customers, pays attention to details at the installation site, and ensures the quality of the project. At the same time, to catch up with the progress of the project, and strive to create a slime drying project for customers as early as possible.

Shaanxi is the key province of Zhengzhou Dingli's construction of slime drying project. Our company has built many slime drying projects in the local area, and has established long-term cooperative relations with many local customers. More customers are welcome to join hands with our company to create a slime dryer project to jointly promote the environmental protection of local slime resources.

Yesterday afternoon, news from Zhengzhou Dingli's workshop showed that the Lebanese charcoal furnace project was successfully loaded and shipped, and all work arrangements are in place. It is expected to arrive in port on time and start shipping on time.

This is also the first time that Zhengzhou Dingli Carbonization Furnace products have entered Lebanon in 2020. Our company guarantees on-time production and delivery, and after-sales installation and other work will follow the progress and ensure safety.

Environmentally-friendly drum continuous carbonation machine uses the carbonized flue gas purification into combustible gas generated in combustion itself. it can continuous product 24 hours. It has an advantages of zero pollution, zero emission, save labor, high capacity, energy-saving consumption, the high degree of automation and advanced technology. Which is suitable for large-scale production, with high carbonation rate, high carbon production rate, energy saving, environmental protection, high efficiency advantages.

Our main products include charcoal making machine, rotary dryer, wood pellet machine, biomass pallet machine, dehydration machine and so on. Warmly welcome new and old customers to our factory to discuss cooperation and seek common development.

The customized wood chip dryer equipment of Malaysian customers in our company has been completed and was successfully loaded and shipped yesterday, adding another successful case for our company's wood chip dryer in overseas markets.

Sawdust dryer is our company's main product, mainly designed and manufactured for the drying of wood processing by-products such as wood chips, wood flour, sawdust, wood bran, broken wood blocks, crushed bark branches, wood shavings and other materials. The sawdust dryer adopts three-channel rotary drum. Compared with the single cylinder, the thermal efficiency is increased by about 40-55%, and the energy consumption is more than doubled. The basic area is saved by about 65% compared with the single cylinder dryer, and the land occupation cost and project construction cost are lower. It can make full use of the residual heat of the heat medium, reduce heat loss, increase the heat exchange area, and greatly increase the evaporation intensity of the unit volume of the dryer, thereby effectively improving the heat energy utilization rate, reducing the energy consumption, and making the dryer thermal efficiency significantly improved.

Zhengzhou Dingli increased its investment in wood chip dryer technology to achieve the optimization and upgrade of the system structure, mainly taking advantage of intelligence, energy saving and environmental protection as its technical advantages. It has also widely opened up foreign markets, with outstanding achievements, projects spread across five continents, and brand influence strength is rapidly improved.

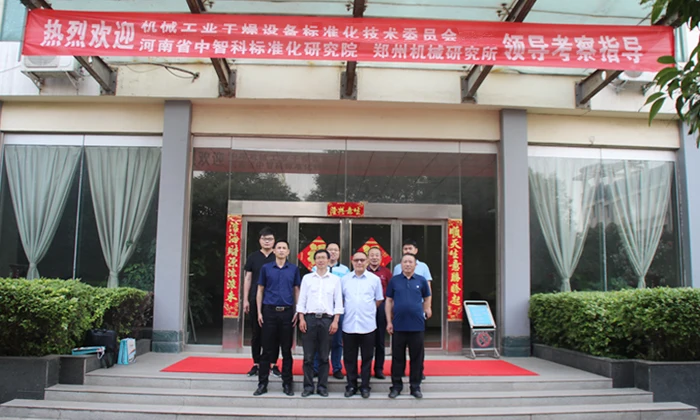

Good news: The academic exchange meeting of the Mechanical Industry Drying Equipment Standardization Technical Committee was successfully launched in our company. Participants were leaders from Henan Zhongzhi Science Standardization Institute and Zhengzhou Machinery Research Institute. And our technical backbone and technical engineers.

Zhengzhou Dingli New Energy Equipment Co., Ltd. is committed to the research and development and production of a series of technical products such as biomass pellet fuel production line, coal (mud) quality upgrading equipment, feed dehydration and drying equipment, kitchen waste disposal equipment, etc., involving kitchen waste Recycling optimization treatment projects, resource recycling projects in the field of circular economy, clean energy and environmental protection projects, distilleries, waste yeast and other winery by-products are converted into feed projects, and coal chemical and coal refining by-products such as slime and coal mines are R & D and production of power plant combustion raw material projects, recycling of wood chips and sawdust resources into biomass energy and other projects.

Zhengzhou Dingli New Energy Equipment Co., Ltd. is a scientific and technological innovative enterprise integrating R & D, design, production and sales in the high-humidity material drying equipment industry. If you are interested in our products, you can get in touch with us by calling, online consultation, etc., we will provide you with professional attitude and caring service.

Li Liuji is the technical backbone of Zhengzhou Dingli group, the founder of Zhengzhou Dingli group, the general director of Zhengzhou Dingli drying research and development center, a visiting professor of Henan University of technology, and one of the top ten technological entrepreneurs in Henan Province. The company has been committed to the technical innovation and research and development of dehydration and drying equipment all the year round. Under Li Liuji's technical innovation and leadership, the technical team has made continuous technical innovation. Its R & D center has a large number of young and middle-aged technical backbones, which promotes the scientific and technological innovation of the R & D center, continuously expands the advantageous position and service field of the enterprise's products, enhances the influence of the enterprise, and drives the technical level up New steps. In cooperation with many domestic scientific research institutes, he has published dozens of academic papers; he has more than 100 national patents, including 5 invention patents, 2 scientific research achievements, 1 science and technology progress award, and the R & D center has various technical personnel.

Dingli group is located at No. 12, Hongye Road, Zhengzhou high tech Development Zone, Henan Province. It is a comprehensive science and technology innovation private enterprise integrating scientific research, development, production, sales and service. Zhengzhou is committed to the R & D and production of a series of technical products, such as kitchen waste treatment equipment, coal (mud) upgrading equipment, feed dehydration and drying equipment, biomass particle fuel production line, etc., involving the optimization treatment project of kitchen waste reuse, resource reuse project in the field of circular economy, clean energy and environmental protection project, waste residue, waste yeast and other by-product transformation of distilleries It is a feed project, coal chemical industry and coal refining by-products such as coal slime and coal stone are transformed into power plant combustion raw materials project, and the research and development and production of projects such as conversion of sawdust and sawdust resources into biomass energy. Since its establishment, Zhengzhou has built hundreds of drying projects, exported equipment to more than 30 countries on six continents, including Asia, Africa, North America, South America, Europe and Oceania, providing users with high-quality dehydration and drying equipment and project construction services.

The large-scale petroleum coke drying equipment purchased by Anhui customers in our company has arrived at its destination, and the installation process began yesterday. The following is a picture sent back by the staff from the scene:

Different types and sizes of drum dryers have different operating environments and drying materials, and different installation technical requirements and planning. Large-scale drying equipment installation procedures are more detailed, and the installation of the equipment is related to the product quality and production safety of the entire drying equipment. Petroleum coke dryer is a set of large-scale drum dryer installed by our company. The equipment is equipped with complete configuration, good operability and advanced configuration in each production link, and the whole production process is more convenient and efficient.

Zhengzhou Dingli is a large manufacturer specializing in the development of various types of dryers, adhering to the principles of excellent quality and service-oriented, and strives to build a major brand in the domestic and foreign dryer markets.

Tofu (tofu dregs) is a combination of water and oil, and the moisture is not easy to handle. Based on this feature, our company has developed a complete set of okara dehydration and drying equipment.

First, the soybean dregs are dehydrated by high pressure, and most of the water is immediately removed, and then enter the soybean dregs dryer. Under the action of a special feed plate and dry hot air, the okara moves back and forth in the direction opposite to the direction of the fresh and dry hot air, the process stroke is long, the temperature is relatively low, and the material runs slowly; In the dryer, the discharge temperature downstream of drying is only 40 ° C. In the entire production process of drying, the heat energy is fully utilized, and the heat of the bean dregs is even. Therefore, the dregs produced by the drying have good color, no paste, low energy consumption, and low hammering rate.

Soybean dregs dryer is mainly composed of heat source, feed machine, rotating drum, unloader, induced draft fan, ship unloader and distribution cabinet. After the dehydrated wet okara enters the dryer, under the condition that the plates are evenly distributed, the uniform dispersion of the dryer and full contact with the hot air accelerate the heat and mass transfer of drying. In the drying production process, the soybean dregs are discharged from another meteor valve section of the dryer under the action of tilt and heat medium. Through careful analysis and research on the soybean residue, the process parameters of the production line, as well as the selection and design of the technical parameters and structure of each equipment were obtained, and verified by the actual soybean residue drying test. The scheme design fully takes into account the characteristics of high moisture content, high protein content and high viscosity of Okara, and adopts a series of unique processes and processes to solve it to ensure a good drying effect.

For more information about okara dryer, please contact us.

The large-scale Slime Dryer ordered by Shanxi customers was shipped as scheduled yesterday after the workers worked overtime. The company ’s technical staff will then rush to the customer site to guide the installation and conduct technical training.

Zhengzhou Dingli is a scientific and technological innovation enterprise focusing on the production of drying equipment and integrating scientific research, production and sales. The company is located in Zhengzhou High-tech Development Zone. The company has talents gathering and produces more than 100 kinds of products. Products include biomass, coal and other energy drying projects, fly ash, sludge, sand, bentonite, mineral powder and other industrial drying projects, forage, lees, tofu residue, wood chips and other agricultural drying projects. Our equipment supports customized according to production needs, we provide free design solutions, welcome to come to consult!

Dingli furnace chain delivered to Morroco today. This is the fourth time which cooperation between each other. In the next several months,we will begin the cooperation of the Biomass furnace chain and also the steam boiler project.

Dingli hot blast stove is a kind of heat exchange equipment with air as a working medium, which is divided into the direct heating type and indirect type. The hot blast stove is divided into a hand-fired hot blast stove, a chain type hot blast stove, and a burner type hot blast stove according to the furnace type structure. According to the use of fuel, it is divided into biomass fuel hot blast stove, coal burning, gas, fuel oil is hot blast stove and so on. The conventional direct coal-fired hot blast stove includes a combustion furnace, a coal pulverizer, a slag remover, a blower, and other auxiliary equipment. After the coal is burned, the flue gas is directly discharged from the rear of the combustion furnace and enters the subsequent drying equipment due to the coal. The flue gas generated by combustion will carry a large number of soot particles. Therefore, such hot air stoves can only be used for drying products that do not require high cleanliness of hot air, such as compound fertilizer, cement, sand, briquette, sludge, feed. Wait. For those products that require a relatively high degree of cleanliness of the hot air and allow a small number of dust impurities, one can only choose an indirect coal-fired hot blast stove, and the indirect coal-fired hot blast stove is not only complicated in structure, high in manufacturing cost, and expensive. Moreover, the thermal efficiency is low and the energy consumption is large. In response to the limitations of conventional direct coal-fired hot blast stoves and indirect coal-fired hot blast stoves, our company has innovated and developed a clean direct-type coal-fired hot blast stoves.

Welcome your inquiry at any time.

Yesterday, the Anhui Petroleum Coke Drying Equipment project has been assembled, and it has entered the trial operation stage. The following is the scene picture.

Petroleum coke is a kind of building materials. The equipment's internal structure, tight sealing, heat preservation and reasonable supporting measures are widely used in various industries for its advanced technology, reasonable operating parameters, simple and feasible operation. Different from other drying equipment, Petroleum Coke Dryers are higher in working performance and service life than other equipment. In addition, in addition to making petroleum coke materials into building material raw materials, petroleum coke dryers can also add processed petroleum coke to petroleum as a petroleum raw material. In addition to this year, the petroleum coke dryer can dry petroleum coke with a moisture content of 70% to 80% to a finished product with a moisture content of 13%. In addition, the entire process of petroleum coke dryer operation is fully closed, which can not only reduce the environmental pollution but also play a role in energy conservation and environmental protection.

Zhengzhou Dingli is a professional manufacturer of dryer equipment. Our petroleum coke dryer models are complete in specifications and quotations are economical and affordable. Users in need can consult or leave a message online. Dingli welcomes users from all walks of life to consult and inspect!

In the Shaanxi Shenmu coal slime drying project, our company provided the coal slime drying production line equipment (heat source, charging equipment, coal slime dryer, electrical control equipment, dust removal equipment, etc.) to the customer according to the signed contract. Last week, Dingli's after-sales team went to the Shenmu site for installation and commissioning. At present, the Coal Slime Dryer project has been formally put into operation.

The coal slime has the characteristics of high humidity and high adhesion. Dingli's new coal slime dryer uses a special dispersing device to break and dry the bonded coal slime. The contact area between coal slime and hot air is increased, and the heat utilization rate is greatly improved. The dried coal slime can be directly used as fuel.

Dingli is a manufacturer of Coal Slime Drying Equipment. It can provide large, medium and small-sized coal slime drying equipment with stable performance, convenient operation and maintenance, energy-saving and environmental protection, high efficiency and favorable price. At present, Dingli coal slime dryer is selling well in domestic and foreign markets. The equipment has been exported to Russia, Ukraine, Mongolia, and other countries, and has established many benchmark projects in several major coal provinces such as Shanxi, Shaanxi and Inner Mongolia, serving hundreds of customers Construction of coal slime drying project. For more information, you can leave a message or consult online.

At the end of last year, Kazakhstan customers successfully purchased Coal Drying Equipment in our company. At present, the equipment has been completed. The entire set of equipment was formally sent to Kazakhstan after careful inspection by the quality inspection department. The following is a picture of the equipment delivery site.

Kazakhstan's national coal resource geological reserves and hundreds of billions of tons are behind China, the United States, Russia, Australia, India, South Africa and Ukraine, ranking eight in the world, accounting for 4% of the world's total reserves. There are 100 coal fields proven and mined in the country. Customers have abundant coal resources in the local area. They hope to purchase coal dryers to process and use these coal resources. Coal dryers are the main dryer products of Zhengzhou Dingli. Many large coal provinces have settled in China, and they have exported to many countries. The customers are optimistic about our rich project construction experience and chose to cooperate with our company. The export of this equipment to Kazakhstan has once again confirmed our company's foreign markets. It has certain core competitiveness, and our technical team has experience in project construction in Kazakhstan. It is believed that after the equipment arrives in the local area, the installation work will be smoothly carried out. The progress of this project is of continuous concern to everyone.

Zhengzhou Dingli Coal Drying Equipment can meet the daily processing requirements of 300 ~ 3000 tons / day. The equipment can be designed and manufactured according to the local needs of customers. Welcome foreign customers to come to the factory to purchase and negotiate project cooperation.

Although the current international coronavirus epidemic situation is severe, our Zhengzhou Dingli Group has overcome all kinds of difficulties and has now resumed production. Today, Bosnia and Herzegovina's Wood Chip Drying And Granulation Production Line was successfully delivered.

In the Wood Pellet Drying And Granulation Production Line, the principle of die roll extrusion molding is used to process biomass raw materials such as agricultural and forestry residues into solid molding fuels to achieve industrialized continuous and stable production. The processing technology route adopts a mixing process that combines primary drying, secondary crushing, continuous feeding and regulating feeding. The pellet molding fuel molding rate reaches 98%, and the bulk density and particle density are high.

The sawdust dryer has a wide range of applications. Bamboo shavings, wood flour, wood shavings, crushed logs and other biomass materials are suitable for this equipment for drying and reprocessing. It is usually used in wood shavings biomass fuel pellet production lines to improve the molding rate of biomass pellets. And molding quality, improve the combustion performance of wood chips biomass fuel. Zhengzhou Dingli has been supplying wood chip drying equipment for many years, and has successfully transformed from a single product supply to a complete set of wood chip biomass fuel production line supply. At present, it has achieved good results and reputation in both domestic and foreign markets.

Customer satisfaction makes our constant pursuit, welcome to visit Zhengzhou Dingli Group.

Today, we have a good news from our production workshop. In order not to delay the production arrangements of Thai customers, we worked overtime during the special period of the international coronavirus epidemic to ensure the quality and the Palm Fiber Dryer was successfully delivered.

Palm Fibers Drying Machine are mainly constituted of heat source , heat exchangers, feeding machine , rotary drum , discharging machine , circulating fan, residue cleaning systems , and power distribution cabinets. With the stirring of lifting flights, silk fibers in the drum are uniformly contacted with hot air. With fast heat and mass transfer, the dried silk fiber is discharged in the outlet. The process parameters of production line and the equipment selection and design are the result of careful analysis of the silk fiber material and verified though the actual test. Our engineers fully take into the factors of flammability, clumping and the wrapped bran residue. We adopt a series of unique original technology and processes to address the above problems, making sure the cleanliness and drying effect of silk fibers.

Palm fiber machines are applicable for the palm silk fiber with 25-40 % MC, quick drying wet materials into dry product with MC below 18%. The fuel selection is wood, straw , husk and other waste ( or coal , natural gas and diesel). This drying machines use thermal oil or hot air as the drying medium, taking advantage of instantaneous temperature difference between high-temperature air and wet materials. The main transmission device adopts electromagnetic or frequency control, equipped with automatic temperature control device. The dried silk fibers keep same color, strength and flexibility.

We do not stop work in special times of international coronavirus. Welcome to consult and order our equipment.

Recently, in order to further promote the cultivation of high-growth enterprises such as gazelle and unicorn enterprises, Zhengzhou High-tech Zone has carried out the identification of gazelle and unicorn enterprises in 2019 in accordance with the requirements of superior documents. After the declaration of enterprises, the selection of third-party organizations, and the review of the relevant departments of the Administrative Committee of the High-tech Zone, a total of 109 gazelle and unicorn companies have been identified. Zhengzhou Dingli is honored to be identified as a potential gazelle enterprise and has now passed the publicity period.

So, what are unicorn companies and gazelle companies?

Unicorn enterprise: Refers to a company that has not been established for more than ten years, has received private equity investment and has not yet been listed, and has a valuation of more than $ 1 billion.

Gazelle Enterprise: Refers to small and medium-sized enterprises that have entered the high growth stage with the support of scientific and technological innovation or business model innovation after starting their business.

Zhengzhou Dingli was identified as a gazelle enterprise this time, which is the recognition of the society and the embodiment of the company's strength. We also believe that with the coming of spring, the company's development will definitely get better and better.

The Chicken Manure Dryer equipment is suitable for fast drying the humidity materials which need to preserve nutrition. By this way, the drying of fresh poultry manure can achieve the purposes of drying, sterilization, deodorant and preservation nutritional.

The Poultry Manure Drying Line is equipped with high-speed rotating drum of crushing devices, which increases the contact area between material and drying medium. The internal unique equipment design, makes materials difficult to adhere to the drum wall panels and parade.The complete machine has the effects of heat preservation, good sealing performance, and the fact that the thermal efficiency considerably. If you are interested in poultry manure dryer, welcome to inquiry.

While welcoming 2020, Dingli also won foreign orders: Dingli and Belgian customers started friendly cooperation on palm residue drying projects. The two parties have officially signed a contract, and our company will provide customers with follow-up services such as palm residue drying production line equipment and project installation and commissioning according to the contract.

Palm residue is the residue after the palm fruit string is defibrated, and it is a good biomass fuel after drying and granulation. The Palm Slag Dryer is designed and manufactured by Dingli Company through a large number of experiments, according to the characteristics of palm residue materials and customer requirements. With a small footprint and other characteristics, the company's technical team can optimize the drying process technology and equipment configuration according to the characteristics of various biomass materials, capacity, application, cost, automation, site conditions, and customer requirements to meet the individual needs of customers.

At present, the technical team responsible for the project has started relevant work to complete the palm residue drying project for customers as soon as possible. Dingli Palm Residue Drying Equipment has various specifications and models that support customization and can meet the needs of domestic and foreign customers to dry palm residue. For more information, you can consult online.

On 13th, December 2019, our old customers from Morroco signed 2 sets of the furnace chain with our company, this is the 4th time they bought the furnace chain from us. This company is a big-sized brick making company in Morroco which has been more than 60 years long history, they use the furnace chain for heating the brick. At the beginning they bought 4 sets and the using effect, so they make the plan to China at the end of October, and order the 2 sets in this month. In the future, we will cooperate in an Olive Pomace Drying Project with each other.

Chain furnace a kind of organic heat carrier furnace is applied most mechanized combustion equipment. It has a reasonable structure, reliable performance, easy installation, and other advantages. Chain grate mainly includes feeding scuttle, base, front axle device, grate device, back shaft drive, observation door (dial fire door), chute, blower, slag machine, and other components. This series of products adopt a light chain belt grate and a reasonable air distribution device also strengthened both side seals of the grate, plus a reasonable allocation of the former arch and rear arch. Combustion adaptability, reasonable combustion air distribution, stoke start fast. Suitable for wood, bagasse, PKS, rice husk, straw, biomass pellet, and other biomass fuel.

Welcome to your visit at any time.

In the Shanxi Coal Slime Drying Plant project, our company provided the customers with the slime drying production line equipment (heat source, loading equipment, slime dryer, electric control equipment, dust removal equipment, etc.) according to the signed contract. After the equipment arrived, the installation and commissioning work was started immediately. At present, the coal slime dryer project is officially put into operation.

The coal slime has the characteristics of high humidity and high adhesion. The traditional dryer has not been able to target this feature. The special Coal Slime Dryer uses a special dispersing device to break up the bonded slime and dry it. The contact area between the slime and the hot air is increased, and the heat utilization rate is greatly improved. The dried slime can reduce the moisture to less than 12% at one time, and the dried coal slime can be directly used as a fuel, which makes the coal slime into treasure.

Dingli new type coal slime drying system has stable equipment performance, convenient operation and maintenance, energy-saving and environmental protection, high efficiency, and favorable price. Welcome to consult online.

Our Indian customers signed the Sand Rotary Dryer with us on 18th Nov. 2019. This is the first cooperation of the sand dryer in the Indian market, they will have 5 sand drying projects, this is just one of them, this explores great sand drying industry market in India, both sides hope long and good cooperation in the future.

The sand is conveyed to silo by belt conveyor or bucket elevator, and transport to the feed end by the feeder of the silo. The inclination of the feeding pipeline should exceed the natural inclination of materials so that to facilitate sand flowing into the dryer smoothly. The rotating cylinder of the dryer is slightly inclined to the horizon. To feed the material from the higher end and the heat carrier enter from the lower end, such produce adverse contact between them sometimes, they can be fed to the cylinder together. As the cylinder running, the sand carried to the lower side by gravity. In the process of moving forward, the wet raw material being roasted by the heat directly or indirectly to make the raw material to dry quickly, the final products discharge out by belt conveyor or screw conveyor. There is a shoveling plate installed in the Sand Dryer with the function of shoveling the materials up and down, to enlarge the contact area between airflow and materials and to enhance the efficiency and make the material running quickly. The heat carrier is hot air, the flue gas, etc. After the dryer process, It needs a cyclone dust collector to catch the items in the airflow. You should use bag type or wet-type dust collector and afterward discharge the waste gas if you intend to further reduce the dust load of the exhaust.

Please feel free to inquire about our sand dryer.

On November 25th, Korean customers made a special trip from Seoul to Dingli to discuss the process of Sawdust Continuous Carbonization Furnace. After professional answers from our company's senior engineers, the customer admired Dingli's technical level and service. After visited the Dingli production workshop, they immediately signed an order for a 1t/h sawdust continuous carbonization furnace production line.

Dingli's Continuous Carbonization Production Line equipment adopts a new process to avoid the shortage of traditional carbonization equipment. At the same time, it has the advantages of 24-hour continuous production, labor-saving, high output, low energy consumption, and a high degree of automation. It is suitable for large-scale production, with a high carbonization rate and energy saving, environmental protection and efficient advantages. Welcome to inquire online and negotiate with us.

Singapore Customers Visited Dingli Brewery Yeast Dryer

On 20th November 2019, the customers from Singapore visited our Brewery Yeast Dryer,they are one of our old customers who cooperated with our company ten years ago—at that time,they bought a screw dehydrator from our company,the equipment is very good,now they want to explore the brewery yeast drying industry, so they come to visit us.

The brewer’s yeast contains nearly 50% protein, 20% natural fiber, abundant VB and fourteen kinds of minerals like zinc, selenium, and chromium. Meanwhile, the amino acid that could not be produced in the body is highly contained in brewer’s yeast. Our Brewer Yeast Drying Production Line product takes advantage of heat conduction between hot steam and wet materials, realizing the indirect drying process. The core system is consists of the dryer, rack, drive system, scraper device, limiting device, scraping device, feeding device and gas circuit system, which is also equipped with the electric control device and exhaust hood. The design of heat conduction could largely reduce the heat loss from heat media, raising the heat efficiency and lowering the energy cost. Meanwhile, our product also has the advantage of space-saving, user-friendly operation, corrosion prevention, and non-pollution.

Welcome to inquiry our brewery yeast dryer at any time.

Jiangsu Vinegar Drying Equipment Installation And Commissioning Completed

Zhengzhou Dingli's Vinegar grain drying project in cooperation with Jiangsu customers has recently arrived at the installation site. After close cooperation between the customer and the project's technical team, the installation and commissioning have been completed and it will be officially put into production.

The Vinegar Residue Drying Equipment in this project is designed and manufactured by our company to meet the needs of local customers to deal with vinegar residue. This equipment not only takes capacity, handles water demand, etc., but also considers the production cost of customers, and applies a new drying process. While increasing the production volume, the efficiency of the production line can be greatly improved, and the installation work of the equipment is currently proceeding smoothly.

Dingli dedicated to the Feed Residue Drying Equipment industry for more than 16 years, with rich experience and cooperation market, we have developed a variety of dryers for biomass, slag, organic fertilizer, coal, sand, etc. to meet customers' different materials and moisture requirements. Welcome online consultation, and get the free customized solution.

Guizhou Sweet Potato Residue Drying Project Officially Put Into Operation

The 200,000 tons/year large-scale Potato Dregs Drying Production Line project that Zhengzhou Dingli cooperated with Guizhou customers has been officially completed. At present, the equipment is officially put into operation and running well.

The potato dregs dryer is one of our mature product series. It is currently used by many enterprises for the feed utilization of potato dregs. In Guizhou sweet potato slag drying project, according to the customer's needs and local conditions, designed and produced potato residue dehydration + drying production line equipment, the dried materials have good color, good quality, energy-saving, and environmental protection, stable operation, not only can meet the production demand of customers, but also the application of new technology greatly improves production efficiency and saves certain customers. The operating cost, after the equipment is put into production, the customer is very satisfied with the dry product.

Zhengzhou Dingli can provide a variety of specifications of Starch Residue Drying Equipment for the majority of users, suitable for sweet potato residue, cassava residue, potato residue and other materials, production line supporting potato residue dewatering equipment, heat source equipment, dust removal equipment, packaging equipment, etc., equipment support Customized to meet the needs of various capacity potato residue treatment, for more detailed information can email or online consultation.

Jiangsu Vinegar Residue Drying Equipment Arrived At The Installation Site

Dingli and Jiangsu customers cooperated with the vinegar residue drying project. The equipment has arrived at the installation site, and the technical team of the project has started the relevant work, and will soon be completed and put into production.

The Vinegar Residue Drying Equipment in this project is designed and manufactured by our company to meet the needs of local customers to deal with vinegar residue. This equipment not only takes capacity, handles water demand, etc., but also considers the production cost of customers, and applies a new drying process. While increasing the production volume, the efficiency of the production line can be greatly improved, and the installation work of the equipment is currently proceeding smoothly.

Dingli Vinegar Slag Drying Production Line is a rotary drum type, which is dried by high-temperature hot air. The production line mainly consists of dewatering equipment, heat supply source, feeding machine, feeding machine, rotary drum, discharger, induced draft fan, unloader, and PLC electric control cabinet.

Dingli dedicated to the drying industry for more than ten years, with rich experience and cooperation market, we have developed a variety of dryers for biomass, slag, organic fertilizer, coal, sand, etc. to meet customers' different materials and moisture requirements.

Welcome online consultation, and get the free customized solution.

Morroco Customers Visited Our Olive Pomace Drying Plant

A group of our customers from Morroco visited Dingli group for the cooperation of olive pomace drying plant,this is the third time they visited us.The first cooperation between each other is in 2017,since the first wood pellet plant cooperation between us,now the wood pellet plant has been running for more than two years,with high effeciency and steady running,they want to explore the drying plant of olive pomace,so they visited us and do the communication of the olive pomace drying,Morroco is rich in olive pomace,after drying,it can be used as fuel for the boiler.

The customers visited our workshop and we showed our new patent dryer for olive pomace drying,after that we negotiated the equipment price,the next step will discuss the details between each side. Welcome to visit our website and make the inquiry about the dryer,we will be very glad to offer the best service to you.

Congratulations To Dingli For Obtaining The "Intellectual Property Management System Certification"

Recently, Zhengzhou Dingli New Energy Equipment Co., Ltd. obtained the “Intellectual Property Management System Certification” through the certification audit of Zhongzhi (Beijing) Certification Co., Ltd. The scope of Zhengzhou Dingli Intellectual Property Management System Certification is R&D, production, sales of drying system equipment, and intellectual property management related to procurement in the above process. This certification marks Zhengzhou Dingli's intellectual property system construction and corporate management to a new level.

The certification of the intellectual property management system refers to putting intellectual property rights at the strategic level of enterprise management. It regards the concept of enterprise intellectual property management, management institutions, management models, management personnel, management systems as a whole, and defines and strives to realize enterprise knowledge. System engineering of the property rights mission. The company accepts the intellectual property management system certification of China Standard (Beijing) Certification Co., Ltd., which is the first batch of intellectual property management system approved by the National Certification and Accreditation Administration (CNCA) and registered by the national registration authority. (IPMS) One of the third-party certification bodies.

As a high-tech enterprise, the establishment, operation, and improvement of Zhengzhou Dingli's intellectual property management system have effectively enhanced the intellectual property awareness of corporate leaders and employees, mobilized the enthusiasm of employees for invention and creation, and made technological innovations and intellectual property closely integrated, strengthen the core competitiveness of the enterprise.

Philippine Brewer's Grain Drying Project Officially Completed And Put Into Production

The Brewer's Grain Drying Production Line project built by Zhengzhou Dingli in the Philippines has been officially completed, and the equipment is officially put into operation after the test machine. At present, the equipment is running well.

Brewer's Grain Dryer is one of our mature product series. It is currently used by many companies for the feed utilization of beer waste. In the beer brewing drying project in the Philippines, according to the needs of customers, it is designed according to the local conditions. The dry production line equipment can not only meet the production demand of customers, but also the application of new technology greatly improves the production efficiency, saves certain operating costs for the enterprise customers. After the equipment is put into production, the customer is very satisfied with the dry products of the materials. After hard work, follow-up project cooperation will be carried out one after another.

Before the Zhengzhou Dingli, the Yeast Drying Production Line project, pasture drying project, and wood chip drying project were built in the Philippines. In the future, Zhengzhou Dingli is looking forward to cooperating with more local customers to build a drying project for common development.

Shanxi Sweet Potato Residue Drying Equipment Completed Installation And Commissioning

The Sweet Potato Pesidue Drying Plant project that our company cooperates with Shanxi customers has been officially completed. The installation and commissioning work of this project has been completed, and the equipment can be officially put into operation after the equipment test.

In the Shanxi Potato Residue Drying Equipment project, our company provides customers with equipment for dehydration and drying of sweet potato residue. The production line includes heat source equipment, dewatering equipment, drying equipment, dust removal equipment, and electronic control equipment. The production line equipment is customized by our company for the production needs of our customers. At present, the equipment is about to be tested. After the test, our company will provide systematic technical training for local customers to facilitate the commissioning and maintenance of the later equipment.

Shanxi is one of the key provinces for the construction of drying projects in our company. Before that, our company built coal slime dryer, kitchen waste drying project, Coal Drying Production Line, etc. The drying production line has once again settled in the local area, which is of great significance to the development of our local sales strategy. In the future, Zhengzhou is looking forward to working with more local customers to build a drying project. Welcome online consultation and visit to discuss cooperation projects.

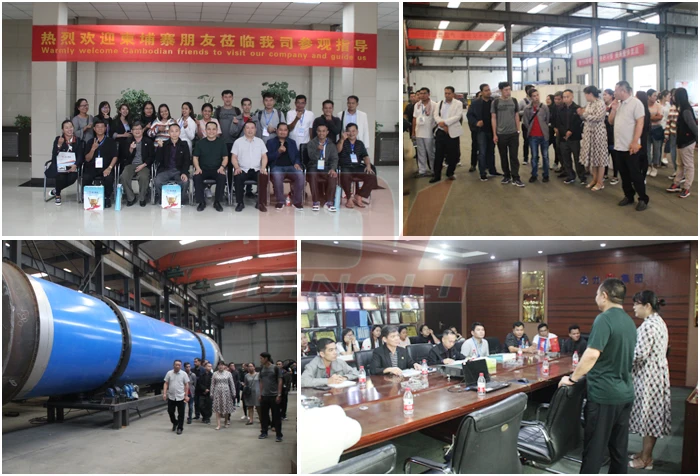

Cambodia Delegation Visited Dingli